The Bunker Hill Mine is renowned for its impressive base metal and silver reserves. It is situated in Kellogg, Idaho, within the Coeur d’Alene Mining District of Shoshone County.

The primary entry point is the 10,000-foot-long Kellogg Tunnel, which is located 2,400 feet above sea level. The tunnel provides access to the deposits located beneath it via three main inclined shafts and additional auxiliary inclines.

The mine is home to over 100 miles of major horizontal openings, as well as six miles of shafts and raises. To access the Kellogg Tunnel, one can take the public road of McKinley Avenue, followed by the Bunker Mine Road that leads to the tunnel’s entrance.

When metal prices are high, mining activities were conducted throughout the year.

Early History of the Mine

In 1885, Noah Kellogg from Murray, Idaho, discovered Bunker Hill. This led to the formation of the Bunker Hill and Sullivan Mining and Concentrating Company in July 1887.

Initially, the upper levels of the mine were mined due to their accessibility through surface portals.

In 1891, a 400-ton-per-day processing plant was built in the main valley at the confluence of Milo Creek and the South Fork of the Coeur d’Alene River to meet the growing mine’s demands. To facilitate the transfer of mineralization to the processing plant, an aerial tramway with a length of 10,000 feet was constructed from Wardner.

Miners working the original Bunker Hill outcrop. 1897, colorized.

During the initial stages of the mining operations, some of the mining tasks were contracted out to leasers, who were rewarded based on the mineral content of the material they delivered to the processing plant.

In 1893, mining operations at Wardner revealed that further progress must require major investment to reach deeper mineralized veins and beds. This led to the construction of the Kellogg Tunnel, which was completed in 1902. It allowed exploration work both on the tunnel level and the intervening ground between the tunnel and the surface.

As a result of this, the Carey, July, and March stopes on the 7th, 8th, and tunnel levels, respectively, were opened. These stopes were some of the most productive and highest-grade stopes in the history of the mine.

Treasure Hunting in Idaho – Coins, Relics & Buried Treasure

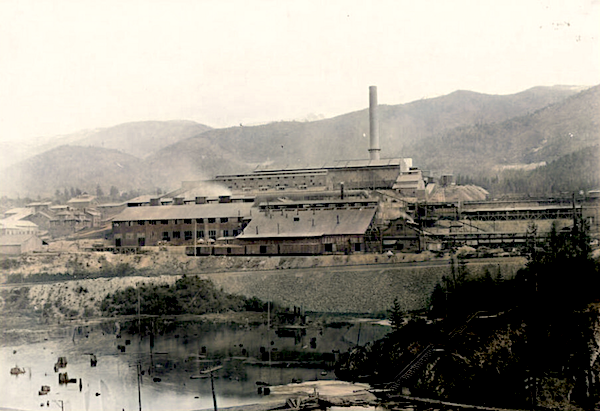

Smelter Construction

The company began public trading in 1905. Construction of a lead smelter was started in 1912, and the facility became operational five years later in 1917. This was soon followed by the development of an electrolytic zinc smelter in 1927.

In 1956, the company name was shortened to The Bunker Hill Company, and operations continued until 1968. That year, The Bunker Hill Company became part of Gulf Resources and Chemical Corporation through a hostile merger.

The Bunker Hill and Sullivan Smelter near Smelterville, Idaho. 1925, colorized.

Metal Production

Throughout its history, the Bunker Hill mine produced an overall total of 42.77 million tons, with an average grade of 8.43% lead, 3.52 oz silver, and 4.52% zinc per ton of ore.

It accounted for 42% of lead, 41% of zinc, and 15% of silver output in the Coeur d’Alene Mining District, and its operations spanned a vertical range of 4,800 ft from 3,200 ft above sea level to 1,600 ft below sea level.

On August 28, 2017, Bunker Hill Mining and Placer Mining Corp. inked a binding agreement for a lease of the Bunker Hill Mine with the option to purchase. Ultimately, on January 7, 2022, BHMC acquired the Bunker Hill Mine from PMC and other private landowners via its wholly-owned subsidiary, Silver Valley Metals Corp.

The silver discovery in the Silver Valley and the Coeur d’ Alene mining district was truly a world-class deposit. Producing lead, silver and zinc, the Bunker Hill Mine has operated on-and-off for over 120 years.

Historic Mining Techniques at Bunker Hill

The primary access to the Bunker Hill Mine is the Kellogg Tunnel at the 9 Level elevation. The shaft extends 4,000 feet down to the 31st level, with the 29th level being the deepest developed. Over 100 years of mining, various methods have been used at Bunker Hill Mine.

In the 1880s, square-set cut and fill was the primary technique employed. To support the walls, timbers were used which were then covered with sand fill pumped down from the surface.

Following backfilling, the level above the sand was then mined, with the broken material being slushed into chutes, which dropped into passes to the level below.

The pillar mining technique was utilized in other areas, employing rib pillars as support instead of timber. To prepare the ground for the next stage, sand fill was pumped in. When the material was blasted, compressed air-operated mucking machines were used to transport it to a chute in the stope, where it fell into a pass to the lower level.

The upper areas of the mine employed sub-level blast hole stoping. Levels were cut at 40-foot intervals using trackless equipment. Long holes were then drilled in the pillars between the levels. Blasting the holes allowed the material to drop to the stope base, which was scooped up by LHDs. These either transported the material to the mine rail haulage system or loaded it onto trucks for direct transportation to the surface.

Mackay, Idaho and the White Knob Mining Company

The Kellogg Tunnel

For areas located above the Kellogg Tunnel, broken material was hauled by trackless equipment and stored in one of two central passes until it could be chute-loaded into the main track haulage system in the Kellogg Tunnel.

Trains powered by battery locomotives transported material from mining areas below the Kellogg Tunnel to bins located at the inclined hoisting shaft. Skips were loaded and hoisted in the shaft to skip dumps located above the Kellogg Tunnel level, where the material was dumped into two massive concrete bins until it could be chute loaded into the tunnel’s main track haulage system.

The material was gravity-drawn from these storage areas and chute-loaded into 22-car trains powered by a 15-ton diesel locomotive and trammed two miles to the surface processing plant bins. The material was then processed into concentrates at the Bunker Hill processing plant.

Rail lines going to the Bunker Hill and Sullivan Mines. 1908, colorized.

Mechanized Mining

In order to boost productivity and enable access to specific areas, diesel-powered equipment was utilized in some areas of the lower mine after 1970. The upper mine (above 9 Level), the region above the Kellogg Tunnel that had not been operated since the 1930s, began to resume major production there in 1972 using bulk mining methods. Diesel equipment was utilized to partially mechanize the upper mine.

Approximately 7,000 tons per week (or 45% of the mine’s total production) were produced by this part of the mine through April 1977.

Later, until the zinc market stabilized, the upper mine was placed on care and maintenance. Using previously broken mineralization, the upper mine’s production was partially restored between 1978 and 1981.

The lower mine resumed production at a rate of roughly 9,000 tons per week after the 1977 strike. The flotation process plant operated in three shifts, seven days a week, at its maximum milling rate of 2,300 tons per day until April 1977. The produced concentrates were railroaded to the lead and zinc smelters.

Remote Gold Mines in Idaho’s Nez Perce National Forest

Environmental Issues

In the 1970s, spurred by increasing public awareness of environmental issues, Bunker Hill made substantial investments to modify their plants to adhere to newly established federal standards on air and water pollution.

Additionally, the company made considerable strides in restoring hillsides in the vicinity which had been damaged by years of airborne smelting effluents and mining-related timbering.

When the mine and smelting complex was shut down in 1981, the EPA put the region on its “National Priority List” for cleanup, which basically put an end to the further development of the Bunker Hill Mine for nearly three decades. The ancient smelter, zinc plant, and surrounding sites have now been thoroughly cleaned.

The Coeur d’Alene mining district has one of the richest silver deposits on Earth. Over the course of mining this region, an estimated 1.18 billion ounces of silver have been mined.

The Rollercoaster of Metal Prices

In 1981, Gulf Resources’ operations in the Bunker Hill mine were adversely impacted by a drop in metal prices, the difficulty of obtaining wage rollbacks from labor, as well as increasingly stringent environmental regulations. As a result, the company chose to terminate operations and sell the Bunker Hill mine to Bunker Limited Partnership in 1982.

While the lead and zinc operations remained closed, BLP reopened the mine in 1988, allowing for exploration, resource definition, mine development, and small-scale production to take place. However, a drop in metal prices in the early 1990s led to the mine’s closure in 1991.

The rights to the mine were given to Robert Hopper of Placer Mining Co. in Bellevue, Washington, in May 1992.

At the time of this writing in late 2022, new interest is being given to the Bunker Hill Mine complex once more. A pre-feasibility study is taking place to consider a $54.8 million dollar investment to reopen parts of the mine for continued extraction of zinc, lead and silver.

The Rich Silver Mines of Aspen, Colorado

Discovery of a Lifetime – A Record-Breaking Silver Nugget Found!